Contact Cement vs Contact Adhesive | Extensive Analysis

Contact cement and contact adhesive are two terms that are often used interchangeably.

However, they have some important differences that you should be aware of before using them.

For general-purpose bonding, contact adhesive may be sufficient. However, for heavy-duty projects or projects that will be exposed to harsh conditions, contact cement may be a better choice.

Here, I will compare contact cement vs contact adhesive to help you understand these differences when choosing an adhesive for your project.

Read More: Rubber Cement vs Contact Cement

What is Contact Cement?

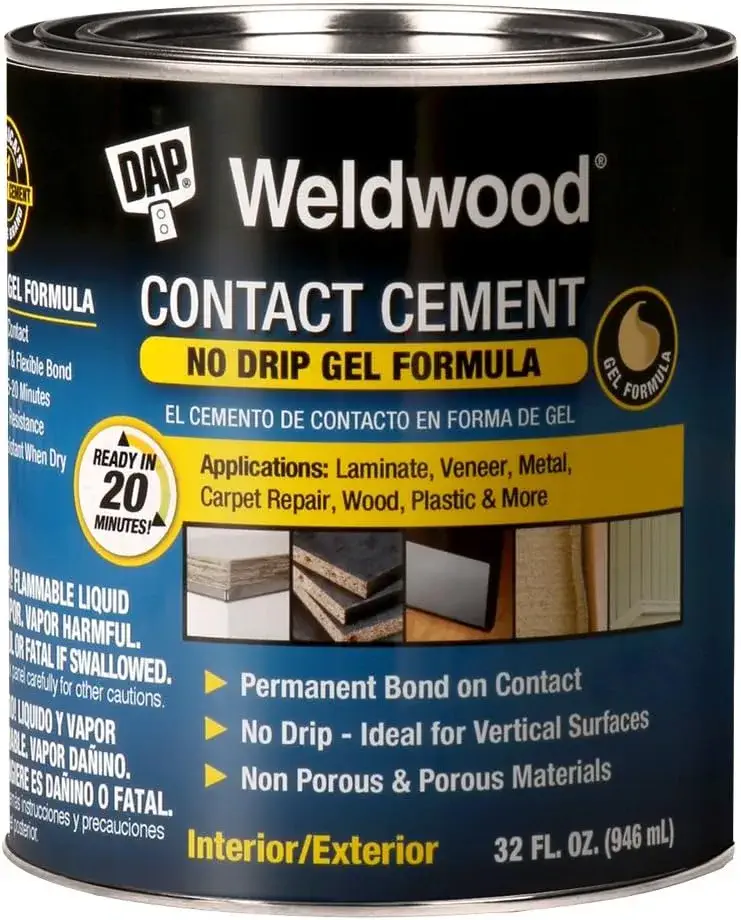

Contact cement is a type of strong, fast-drying adhesive known for its instant bond.

It is typically based on neoprene or polychloroprene rubber and contains a solvent that evaporates upon application, leaving behind a strong, flexible bond.

This type of adhesive is used in a variety of industries, including woodworking, construction, and automotive repairs.

Contact cement creates a powerful bond that offers excellent shear strength and flexibility.

It is ideal for applications where the bonded materials may experience movement or stress, such as attaching laminate to countertops or bonding flexible materials.

Contact cement excels in bonding large surface areas and materials that may be difficult to clamp.

It is widely used in the woodworking industry for bonding laminates, veneers, and edgings to wood substrates.

Additionally, contact cement is commonly employed in the footwear industry for attaching soles to shoes.

Advantages of Contact Cement

- Forms an instant and permanent bond

- Can bond a wide range of materials

- Resists heat, water, and wear

- Ideal for woodworking and laminating projects

What is Contact Adhesive?

Contact adhesive is a more general term that encompasses a broader range of adhesives used for creating strong bonds between materials.

It can be based on various formulations, including rubber, polyurethane, or epoxy. Contact adhesives usually come in two forms: solvent-based and water-based.

Solvent-based contact adhesives contain volatile organic compounds (VOCs) that evaporate upon application, while water-based contact adhesives use water as a carrier.

The bond strength and flexibility of contact adhesive vary depending on the specific formulation.

Some contact adhesives can provide a strong bond with good flexibility, while others may be more rigid.

Polyurethane-based contact adhesives, for example, often offer a durable and flexible bond.

Contact adhesives are more versatile and can be used for various applications. They are suitable for bonding materials such as rubber, leather, metal, foam, and some plastics.

Water-based contact adhesives are often preferred for indoor projects due to their lower VOC content.

Advantages of Contact Adhesive

- Allows for repositioning and adjustment

- Does not produce harmful fumes

- More environmentally friendly

- Ideal for crafts and repairs

Contact Cement vs Contact Adhesive Comparison Table

| Feature | Contact Cement | Contact Adhesive |

| Purpose | Heavy-duty adhesive | General-purpose adhesive |

| Application | Applied to one surface only | Applied to both surfaces to be bonded |

| Bond Strength | Forms a stronger bond than contact adhesive | Forms a weaker bond than contact cement |

| Resistance to heat, water, and wear | High | Varies, depending on the type and quality of adhesive |

| Materials | Used on heavy-duty projects such as wood, metal, and plastic | Used on a variety of materials such as paper, cardboard, and fabrics |

How Do Contact Cement and Contact Adhesive Differ?

Contact adhesive and contact cement are both types of adhesives used to bond materials together, but they have some differences in their properties and applications.

Composition

Contact adhesive is a type of adhesive that is typically water-based and contains synthetic rubber, neoprene, or polychloroprene.

It is sometimes referred to as “rubber cement” and is commonly used for bonding porous materials like fabric, paper, wood, and some plastics.

Contact cement, on the other hand, is solvent-based and contains neoprene, nitrile, or other types of rubber.

It is often sold as a thick, viscous liquid and is primarily used for bonding non-porous materials such as metal, plastic laminates, leather, and rubber.

Application and Drying Time

When using contact adhesive, both surfaces to be bonded are coated with the adhesive and allowed to dry before they are pressed together.

The drying time for contact adhesive is relatively short, usually a few minutes.

The contact cement must be applied to both surfaces to be bonded, and it must be allowed to dry completely on both surfaces before they are pressed together.

Once the cement is dry, the two surfaces are joined, and the bond is typically immediate.

Bond Strength and Flexibility

Contact adhesive creates a flexible bond, which is useful for materials that may undergo some movement or flexing.

It can handle a certain amount of stress and movement without breaking the bond.

Contact cement creates a very strong and permanent bond.

It forms a rigid bond that is resistant to both heat and water, making it suitable for applications where high strength and durability are required.

Bonding Surfaces

Contact adhesive is suitable for bonding porous materials like wood, foam, paper, fabric, cork, etc.

Contact cement is best used for bonding non-porous materials like plastic laminates, metal, leather, rubber, certain plastics, etc.

Application Method

Typically applied using a brush, roller, or spray for even coverage on the bonding surfaces.

Generally applied using a brush, roller, or even a spatula, but not sprayed, as the solvents in contact cement are highly flammable.

Read More: E6000 vs Contact Cement

Frequently Asked Questions (FAQs)

What Is the Difference Between Cement and Glue?

The difference between cement and glue is that cement is a specific type of adhesive that is used for construction purposes, while glue is a general term for any substance that can stick two surfaces together.

Cement is made from a mixture of aluminum, silicon, calcium, and iron and when mixed with water and other materials, it can be used to make mortar and concrete.

Glue can be made from various materials, such as petrochemicals, rubbers, or epoxies, and can be used for various purposes, such as crafts, repairs, or electronics.

Cement is usually stronger and more durable than glue, but also heavier and less flexible.

Glue is usually lighter and more versatile than cement, but also weaker and less resistant to heat or water.

What Can I Use Instead of Contact Cement?

If you don’t have contact cement or want to use a different product for your project, you can try some alternatives that have similar properties or functions.

Some possible alternatives are:

- Super glue: A fast-drying and strong adhesive that can bond many materials

- Epoxy: A two-part adhesive that can bond and fill gaps between materials

- Hot glue: A thermoplastic adhesive that can bond and seal materials

- Spray adhesive: An aerosol adhesive that can bond large or irregular surfaces

How Long Does Contact Cement Last?

Contact cement can last for a long time if stored and used properly. The shelf life of contact cement depends on the type and brand of the product.

Generally, contact cement can last for up to two years if unopened and stored in a cool and dry place.

Once opened, contact cement should be used within six months or as directed by the manufacturer.

To extend the life of contact cement, you should:

- Keep the lid tightly closed when not in use

- Make sure the product is not exposed to extreme temperatures or humidity

- Stir the product well before each use

- Use a clean and dry applicator

- Discard any product that has thickened or hardened

Why Is It Called Contact Adhesive?

Contact adhesive is so named because it is usually applied to both surfaces to be bonded. As the solvent evaporates, the two surfaces can be joined to form a strong bond with high shear resistance.

What Is Contact Adhesive Used For?

Contact adhesive can be used for various purposes and projects that involve bonding different materials together. Some common uses are:

- Crafts and hobbies: Contact adhesive can be used to glue paper, fabric, foam, felt, leather, and other materials for making cards, scrapbooks, models, costumes, and more.

- Repairs and maintenance: Contact adhesive can be used to fix tears, holes, cracks, or loose parts in items such as shoes, bags, furniture, appliances, and more.

- Upholstery and automotive: Contact adhesive can be used to attach fabrics, vinyl, carpets, headliners, and other materials to surfaces such as seats, dashboards, doors, and more.

Final Thoughts

Contact cement and contact adhesive are both powerful adhesives that can bond various materials together.

Hopefully, this comparison between contact cement vs contact adhesive has helped you understand the differences between them.

Contact cement is more suitable for heavy-duty applications that require instant and permanent bonds.

Contact adhesive is more suitable for applications that require some flexibility and repositioning before the bond becomes permanent.

Both adhesives require proper preparation, application, and curing to ensure a strong and lasting bond.